Introduction

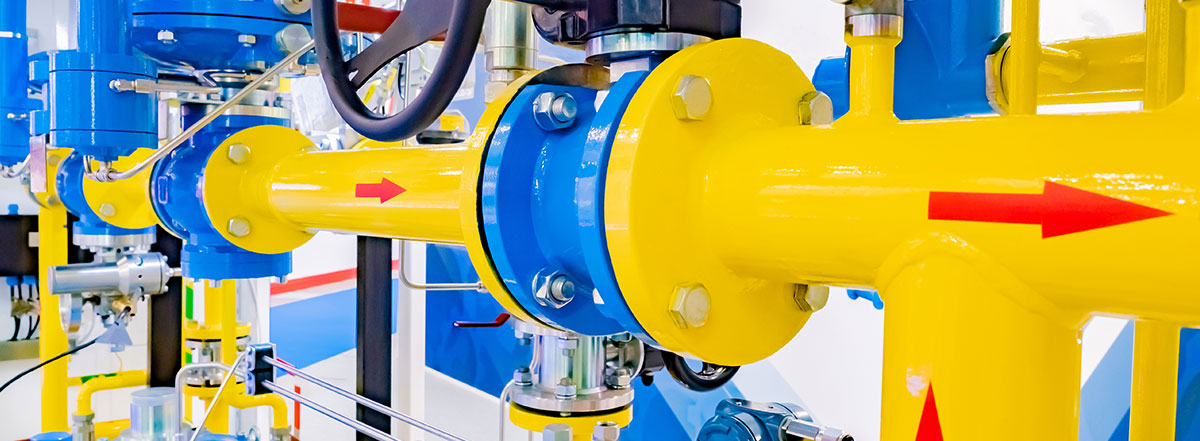

In the frenetic world of heavy industry, where strength and dependability are of the utmost importance, heavy hex bolts stand tall as the unsung heroes, keeping together the backbone of the construction of ship engines and petrochemicals. In some of the most demanding locations, these sturdy fasteners are essential in assuring safety, stability, and longevity, in addition to their other benefits.

Why are heavy hex bolts in high demand in the petrochemical and ship engine manufacturing industries?

People who work with petrochemicals and make ship engines need heavy hex bolts for several reasons:

-

Strong and long-lasting: Heavy hex bolts are made to work in harsh circumstances, like high pressure, changing temperatures, and places that rust. Their strong construction ensures structural stability, preventing them from failing in critical situations.

-

Secure Fastening: The hexagonal shape of the heads of these bolts gives them a larger bearing area, which lets you use more torque when installing them. This keeps the link tight and safe, which is important for handling the high vibrations and stresses in petrochemical plants and ship engines.

-

Corrosion Resistant: Standard bolts rust and deteriorate in corrosive conditions like petrochemical plants and maritime applications. This requires corrosion resistance. The equipment and structures they fasten have a longer lifespan thanks to heavy hex bolts, which are very resistant to corrosion, particularly when manufactured from materials like stainless steel or coated with certain compounds.

-

Standardization: Manufacturers of petrochemicals and ship engines follow strict industry standards to guarantee the dependability and safety of their products and processes. When it comes to heavy hex bolts, stakeholders can rest easy knowing that they are engineered to meet or surpass standards like ASTM A193 and A194.

The Roll-Fast Edge

Roll-Fast understands the essential significance heavy hex nuts and bolts play in these sectors. As a leading manufacturer specializing in high-tensile bolts and nuts, we provide a complete selection of products customized to the specific needs of petrochemical and ship engine applications:

-

A193 B7 Double End Stud Bolts, A194 2H Hex Nuts: These fasteners are designed to resist harsh circumstances and meet the most stringent ANSI, ASME, and ISO requirements, making them perfect for use in petrochemical facilities and ship engines.

-

Specialized Coatings: Our heavy hex bolts come in a range of finishes, including hot-dip galvanized, PTFE, Geomet, and Dacromet, which improve their corrosion resistance and durability in tough conditions.

-

Wide Range of Products: From spherical screws and expansion screws to turning parts and stud bolts, we provide a broad range of fasteners to our customers in the petrochemical and ship engine production industries.

Conclusion

Heavy hex bolts, such as Astm A193 b7, A193 b16, A193 b8, and B7m are dependable, long-lasting, and strong enough to withstand the harsh circumstances in the production of petrochemicals and ship engines. With great pride, Roll Fast stands at the forefront of bolt manufacturing. Every customer finds their demands satisfied through our broad range of top-tier goods. Globally, our sturdy hex bolts are the go-to for professionals in various fields - they're clutch for keeping key equipment steady in petrochemical setups and ensuring the smooth sailing of vessels.